For us as a roastery, the most important processing step for the unique coffee taste is definitely roasting the coffee. Our job here is to find the perfect roasting profile for each coffee. What is particularly important to us is where the coffee comes from, how it was grown and processed and what variety it is. Based on all of this information, an individual roasting profile is then created for each coffee, which is intended to specifically highlight the unique taste of the coffee specialties from the countries of origin.

In order for the characteristic taste of coffee to develop, the green coffee must go through a number of steps after harvesting. Immediately after harvesting, the ripe cherries are sorted so that only the best cherries are processed into high-quality green coffee. The sorted cherries are usually processed into microorganisms. After sorting, processing follows, i.e. the process in which the pulp is separated from the core, the green coffee bean. The green coffee is then packaged and exported. Once the green coffee finds its way to us at the Wildkaffee roastery, a very important step begins - roasting the coffee bean.

What happens when coffee is roasted?

When the coffee bean is roasted, the raw coffee is "dry heated". This is intended to trigger the chemical Maillard reaction, in which the amino and sugar acids contained in the bean find a new composition. This creates new flavors. After the coffee bean has actually been roasted, the roasting reaction actually continues for around 12 hours. It takes around 72 hours for this to completely subside. In order for the flavor of the coffee to fully develop, the coffee should not be used for preparation until around a week after the coffee bean has been roasted. This is the best way to allow the unique flavors and fine notes to develop.

Quality control

To ensure that the selected green coffee varieties from the various countries of origin can best develop their unique individual taste, a separate roasting profile is created for each coffee. This is done after numerous test roasts of small quantities and the tasting of the respective coffees.

This allows the taste of the coffee to be evaluated and compared depending on the degree of roasting. Ultimately, the roasting profile is designed in such a way that only the best variety of flavors is extracted from the coffee through roasting.

The different stages of roasting coffee

When roasting coffee beans, we generally distinguish between three different roasting levels – light roast, medium roast and dark roast.

Light coffee roasts - Specialty Coffee

With the light roast, the coffee is roasted for a shorter time and at a lower temperature (approx. 196 degrees). This gives the beans a light brown color. The shorter roasting time at a lower temperature means that the acids remain in the beans. The taste highlights the complex acidity, which is particularly popular with specialty coffees.

Medium coffee roasts - Coffee

Medium roasts are roasted a little longer and at a higher temperature (around 215 degrees). This creates a balanced relationship between body and noticeable acids, which bring a pleasant fruitiness to the cup profile.

Dark coffee roasts - Espresso

With dark roasts, the beans are roasted for longer and at a higher temperature (around 235 degrees). This means that the coffee contains hardly any acids and develops intense roasted aromas that produce a chocolaty, nutty taste.

Artisanal roasting of coffee

We at the Wildkaffee Roastery are advocates of the artisanal roasting method. The green coffee is roasted particularly gently and over a longer period of time. This gives the coffee beans more time. Depending on the variety, the roasting takes between 10 and 20 minutes at temperatures between 190 and 230 degrees. After roasting, the beans are placed on a special sieve, where they are cooled down to the desired temperature within a minute. In our coffee roastery we work with two roasters: the IMF RM60 & the Loring S35 Kestrel.

The industrial roasting of coffee

When coffee beans are roasted industrially, huge barrel roasters are used. These operate at temperatures between 400 and 800 degrees. This means that the roasting process only takes between 2 and 7 minutes and significantly larger quantities of coffee can be processed. To prevent the coffee from continuing to roast, even after it has left the roaster, it is sprayed with small amounts of water so that it can cool down. This causes the coffee to develop slightly sour notes.

Crafts vs. industry - the difference explained

If we compare the artisanal roasting of coffee beans with the industrial version, it becomes clear how the two processes differ and which aspects are emphasized. With artisanal roasting, the focus is on specifically highlighting the unique taste of a wide variety of coffee specialties. With industrial roasting, it's about consistent taste and a large amount that can be processed in a very short time. Which variant you prefer is up to you, because tastes and preferences are different.

What steps are involved in roasting coffee?

In the first step of coffee roasting, the still green bean loses most of its liquid content. This phase is also known as the drying phase. Little by little, the color of the bean changes, slowly taking on a yellowish tone - a sign that the Maillard phase is beginning. The carbohydrates and amino acids react with each other and change their structure. The sugar molecules begin to caramelize and the beans take on the typical brown color. Little by little, the temperature in the roaster and in the bean rises steadily, so that the coffee is exposed to more and more pressure. If the bean can no longer withstand this pressure, a slight breaking sound can be heard, which is known in technical terms as the "first crack". After the first crack, the development phase begins. This is when the unique taste and complex aromas form in the coffee. To ensure that this taste is retained, the roasting process is stopped shortly after the first crack.

The roasting master and his tasks

Who is actually behind our roasted coffee beans? For several years now, our master roaster Josef Staltmayr has been processing the high-quality green coffee that comes directly from our partner farmers in a wide variety of countries. Together with founder Leonhard Wild, regular trips are made to the farmers to check the quality of the green coffee directly on site and to track down new trends in the coffee world.

But roasting is not the only task of our roasting master. Our coffee is constantly checked to ensure that the roasting profile and quality always remain at the highest level. For this, regular cuppings, i.e. tastings, must be carried out, which also determine which beans are actually processed.

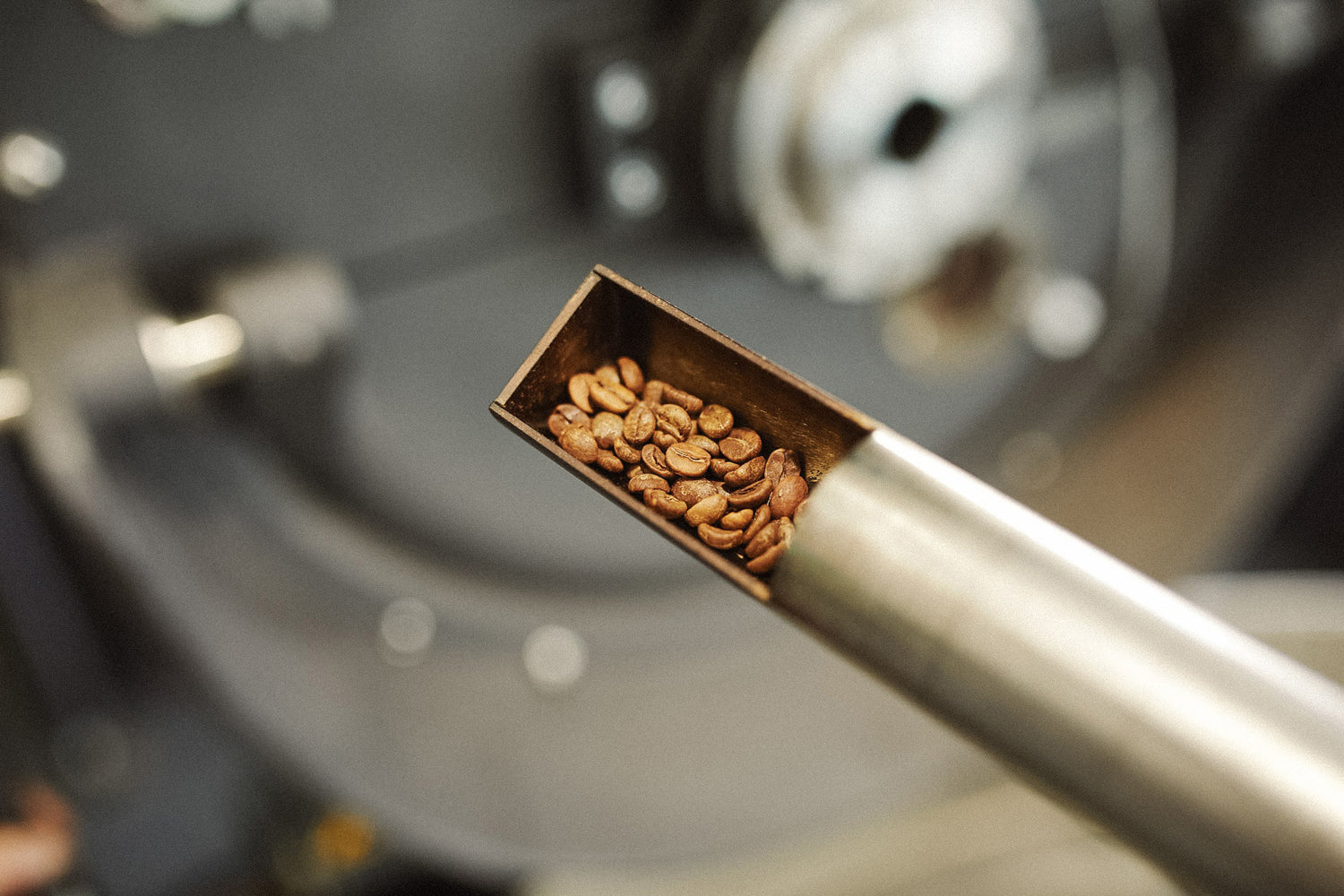

Sample Roast - sample roasting as quality management

The test roasts, which are carried out with small quantities, so-called samples, before the green coffee is received or ordered, are also particularly important. This allows an optimal roasting profile to be achieved, in which only the best flavors find their way into your cup profile. Furthermore, the roasting master can use the samples to determine the quality of the beans and thus also make a targeted decision about which coffees find their way into our coffee roastery.

Discover our Wildkaffee classics

-

Hausespresso

Hausespresso

Hausespresso- Regular price

-

€12,10 EUR €33,46 EUR - Regular price

-

- Sale price

-

€12,10 EUR €33,46 EUR - Unit price

-

€34,57 EUR per kg

-

Wilderer Espresso

Wilderer Espresso

Wilderer Espresso- Regular price

-

€12,10 EUR €33,46 EUR - Regular price

-

- Sale price

-

€12,10 EUR €33,46 EUR - Unit price

-

€34,57 EUR per kg

-

Wildsau Espresso

Wildsau Espresso

Wildsau Espresso- Regular price

-

€13,12 EUR €35,49 EUR - Regular price

-

- Sale price

-

€13,12 EUR €35,49 EUR - Unit price

-

€37,49 EUR per kg

-

El Salvador - Coffee School Project

El Salvador - Coffee School Project

El Salvador - Coffee School Project- Regular price

-

€13,72 EUR €36,51 EUR - Regular price

-

- Sale price

-

€13,72 EUR €36,51 EUR - Unit price

-

€39,20 EUR per kg